Industrial ovens are widely used across many industries and applications, from food processing to manufacturing. Whether you’re an engineer, a chef, or just curious about modern technology, this article will give you an overview of the various uses for industrial ovens.

From baking bread to welding metal components together, industrial ovens have been instrumental in creating more efficient production processes and delivering better products with improved quality control. We’ll cover how these powerful tools work and examine some of their most common applications around the world today.

So get ready to bring in the heat as we explore the wide range of potential that lies within industrial ovens!

Powder Coating: Finishing Automotive Parts with Heat-Cured Paint in Industrial Ovens

Powder coating is one of the most popular methods for finishing automotive parts. It involves applying heat-cured paint in an industrial oven and then curing it at high temperatures.

This process allows for a durable finish that can withstand extreme weather conditions, making it ideal for outdoor applications. The powder coatings come in various colors and textures, giving you the option to customize your car’s exterior look with ease.

Additionally, the powder coating process helps protect against corrosion and other environmental hazards such as UV exposure or saltwater damage. By utilizing an industrial oven to complete this task, you get a consistent finish every time while also ensuring that no hazardous chemicals are released into the air during application or curing processes.

From its ability to protect from corrosion to its customization options, powder coating with an industrial oven is quickly becoming one of the go-to solutions when it comes to finishing automotive parts today.

Metal Hardening: Forging Steel and Alloys for Strength & Durability

.jpg)

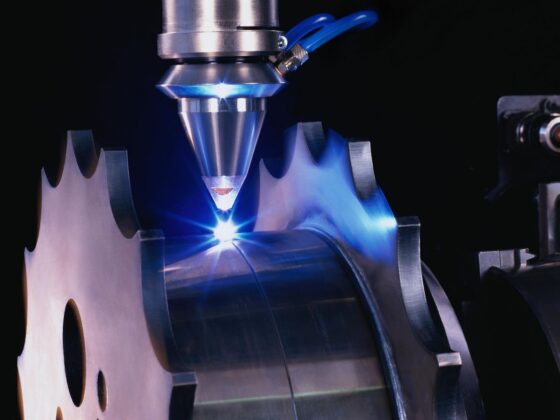

Industrial ovens are a powerful tool in the process of metal hardening. Heat treatments, such as forging and tempering, can transform metals into stronger and more durable alloys that are capable of withstanding intense conditions.

Forging steel and other alloys requires precise temperature control to ensure optimal results. Industrial ovens provide this accuracy by allowing operators to heat materials quickly and evenly before cooling them back down to room temperature at an equally optimized rate.

This helps prevent warping or cracking while also helping to create the desired strength and durability of the metal alloy being treated. By using industrial ovens, engineers can craft components made from strong yet lightweight metals that remain tough enough for any application they may be used for.

Testing Laboratories: Analyzing Materials Through Temperature Control in Industrial Ovens

Industrial ovens are essential tools for any testing laboratory looking to accurately analyze materials. Temperature control is one of the key features of industrial ovens, allowing laboratories to carefully examine how materials react in different environments.

Testing labs use temperature-controlled ovens to simulate extreme temperatures and conditions that can’t be achieved through natural means. By utilizing advanced software and hardware, these ovens provide precise temperature regulation, which helps technicians measure changes in material properties with greater accuracy.

With this technology, laboratories can more precisely identify flaws or weaknesses in a range of materials from metals and plastics to ceramics and composites. Industrial ovens also offer huge time savings when compared with manual processes because they allow tests to progress much faster than before due to their automated nature; this boosts efficiency while reducing costs associated with long test runs.

Ultimately, using an industrial oven provides the perfect platform for analyzing materials efficiently and accurately within a laboratory setting – providing valuable insights into product quality assurance across industries such as aerospace and automotive engineering.

Conclusion

Industrial ovens are a key component of many industries, from food production to automotive manufacturing. Not only do they help fulfill the needs of specific applications, but they also bring in the heat for various processes.

Whether it’s baking cookies or curing paint on car parts, industrial ovens can help get the job done faster and more efficiently. For those seeking precision temperature control when using an industrial oven, Chiuvention Climate Chambers‘ wide range of industry ovens provide reliable results with all types of products and materials.

With their state-of-the-art technology and superior durability, these industry ovens are sure to deliver optimal performance every time.